A Comprehensive Guide to the Top 3D Printing Projects for 2023

Related Articles: A Comprehensive Guide to the Top 3D Printing Projects for 2023

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to A Comprehensive Guide to the Top 3D Printing Projects for 2023. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

A Comprehensive Guide to the Top 3D Printing Projects for 2023

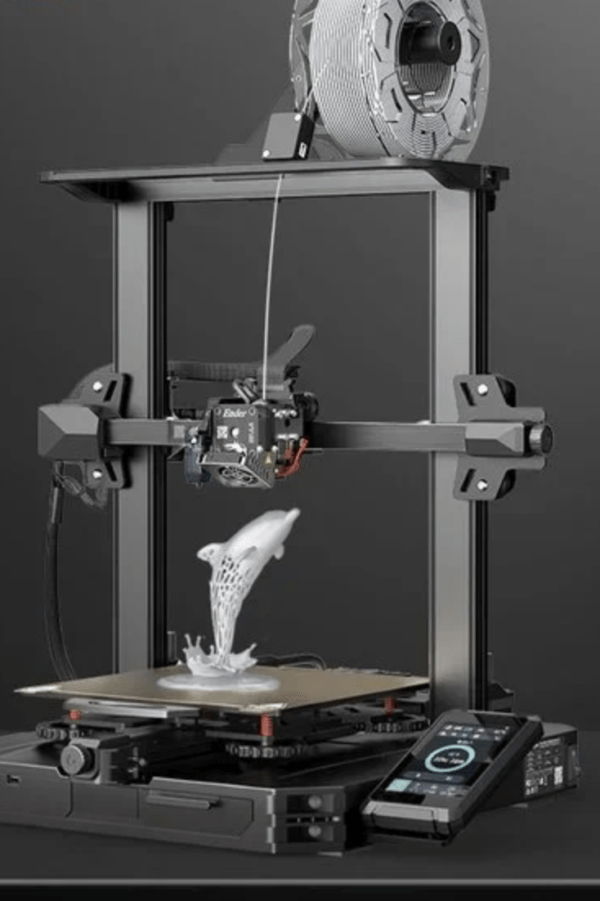

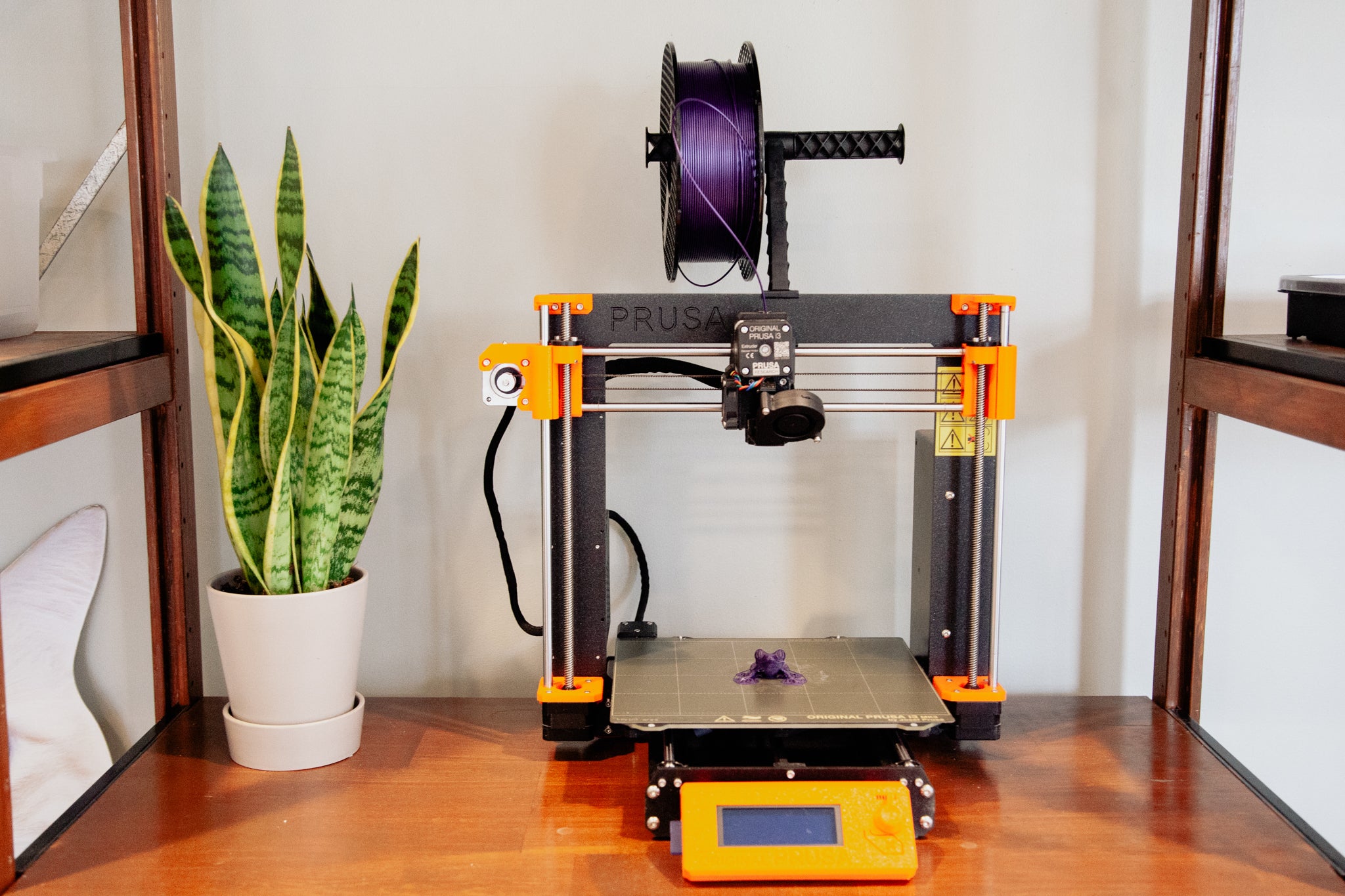

The world of 3D printing continues to evolve at a rapid pace, offering an ever-expanding range of possibilities for both hobbyists and professionals. From intricate models to functional prototypes, the technology empowers individuals to create objects previously unimaginable. As we delve into 2023, several trends emerge, highlighting the most compelling and impactful 3D printing projects.

1. Functional Prototypes and Customizations:

3D printing has become an indispensable tool for engineers, designers, and product developers. The ability to rapidly create prototypes allows for iterative design processes, reducing development time and costs. This is particularly crucial in industries like automotive, aerospace, and medical devices, where precision and functionality are paramount.

Benefits:

- Accelerated Design Cycles: 3D printing enables rapid prototyping, facilitating quick iteration and refinement of designs.

- Cost Reduction: Prototyping with 3D printing eliminates the need for expensive tooling and molds, reducing overall development costs.

- Enhanced Functionality: 3D printing allows for intricate designs and complex geometries, enabling the creation of highly functional prototypes.

- Customizations: 3D printing empowers the creation of customized prototypes tailored to specific needs and applications.

FAQs:

- What materials are best suited for functional prototypes? The choice of material depends on the specific application. ABS, PLA, nylon, and carbon fiber reinforced plastics are commonly used for their strength, durability, and heat resistance.

- How can I ensure the accuracy and functionality of my 3D printed prototypes? Calibration of the 3D printer and use of high-quality materials are crucial for achieving accurate and functional prototypes. Employing design software with simulation capabilities can further enhance the process.

Tips:

- Utilize CAD software: Leverage CAD software for precise design and model creation, ensuring accurate representation of the prototype.

- Optimize for 3D printing: Design with printability in mind, considering factors like overhangs, support structures, and material properties.

- Test and iterate: Conduct thorough testing of the prototype to identify any design flaws or areas for improvement.

2. Personalized and Customized Products:

The ability to create unique and personalized products is a significant advantage of 3D printing. From custom jewelry and home decor to personalized medical devices and prosthetics, the technology empowers individuals to design and manufacture objects tailored to their specific needs and preferences.

Benefits:

- Uniqueness and Individuality: 3D printing allows for the creation of truly unique products, reflecting personal style and preferences.

- Customization for Specific Needs: Products can be customized to fit individual requirements, providing optimal comfort and functionality.

- Enhanced Personalization: 3D printing enables the integration of personalized elements, such as names, dates, or logos, adding a unique touch to products.

- Mass Customization: 3D printing allows for the production of customized products on a larger scale, catering to diverse individual needs.

FAQs:

- What types of materials are suitable for creating personalized products? A wide range of materials can be used, including resins, metals, and ceramics, depending on the desired aesthetic and functional properties.

- How can I design and create personalized products using 3D printing? Various online platforms and design software tools are available to assist with designing and creating personalized products, offering templates, customization options, and 3D printing services.

Tips:

- Explore design software: Experiment with design software specifically tailored for 3D printing, allowing for intricate detailing and personalization.

- Utilize online platforms: Leverage online platforms that offer 3D printing services and design templates for personalized products.

- Consider material properties: Select materials that align with the intended use and aesthetics of the personalized product.

3. Educational and STEM Tools:

3D printing has emerged as a powerful tool for education, particularly in STEM (Science, Technology, Engineering, and Mathematics) fields. The technology allows students to visualize and interact with complex concepts, fostering hands-on learning experiences and sparking creativity.

Benefits:

- Engaging Learning Experiences: 3D printing provides students with tangible, interactive models, enhancing their understanding of abstract concepts.

- Problem-Solving and Design Thinking: Students can design, print, and test their own creations, developing critical thinking and problem-solving skills.

- Project-Based Learning: 3D printing facilitates project-based learning, encouraging students to apply their knowledge and skills to real-world problems.

- Increased Accessibility: 3D printing makes advanced technology accessible to students, providing opportunities for hands-on experimentation and exploration.

FAQs:

- What types of projects are suitable for 3D printing in education? A wide range of projects can be undertaken, from simple models to complex mechanical devices, allowing students to explore different disciplines.

- How can teachers integrate 3D printing into their curriculum? Teachers can incorporate 3D printing into existing lessons, designing projects that require students to utilize the technology and apply their knowledge.

Tips:

- Develop age-appropriate projects: Design projects that are engaging and challenging for students at different age levels.

- Provide adequate support: Offer clear instructions, tutorials, and technical support to ensure students can effectively utilize 3D printing technology.

- Encourage creativity and experimentation: Promote a culture of innovation and exploration, encouraging students to think outside the box and experiment with different designs.

4. Architectural Models and Design Visualization:

3D printing has revolutionized architectural design, allowing architects to create highly detailed and accurate models of buildings and structures. These models provide valuable tools for visualization, communication, and client presentations.

Benefits:

- Enhanced Visualization: 3D printed models provide a tangible representation of architectural designs, enabling better visualization and understanding.

- Improved Communication: Models facilitate clear communication between architects, clients, and stakeholders, reducing ambiguity and misunderstandings.

- Client Engagement: 3D printed models enhance client engagement, providing a more immersive and interactive experience.

- Design Iteration and Testing: Models allow for experimentation with different design elements and the identification of potential issues before construction.

FAQs:

- What materials are commonly used for architectural models? Materials like PLA, ABS, and resin are commonly used, offering a balance of strength, detail, and affordability.

- How can I create detailed architectural models using 3D printing? Specialized CAD software and 3D printing services are available, catering to the specific needs of architectural modeling.

Tips:

- Utilize professional-grade software: Employ specialized CAD software designed for architectural modeling, ensuring accuracy and detail.

- Consider scale and detail: Choose the appropriate scale and level of detail for the model, balancing accuracy with practicality.

- Enhance with paint and finishing: Apply paint, textures, and other finishing techniques to enhance the visual appeal and realism of the model.

5. Medical Devices and Prosthetics:

3D printing is playing an increasingly important role in the medical field, enabling the creation of custom medical devices, prosthetics, and implants. The technology offers a personalized approach to healthcare, providing patients with tailored solutions that meet their specific needs.

Benefits:

- Personalized Solutions: 3D printing allows for the creation of custom medical devices and prosthetics tailored to individual anatomy and requirements.

- Improved Functionality: Customized solutions enhance functionality and comfort, improving patients’ quality of life.

- Reduced Costs: 3D printing can reduce the cost of manufacturing medical devices, making them more accessible to patients.

- Faster Production: 3D printing enables rapid prototyping and production, reducing wait times for patients in need of medical devices.

FAQs:

- What materials are used for 3D printed medical devices? Biocompatible materials like PEEK, nylon, and titanium are commonly used, ensuring safety and compatibility with the human body.

- How are 3D printed medical devices designed and manufactured? Specialized software and 3D printing techniques are employed, utilizing patient-specific data and advanced manufacturing processes.

Tips:

- Collaborate with medical professionals: Partner with medical professionals to ensure the design and functionality of 3D printed devices meet clinical standards.

- Utilize biocompatible materials: Choose materials that are safe, non-toxic, and compatible with the human body.

- Maintain strict quality control: Implement rigorous quality control measures to ensure the safety and effectiveness of 3D printed medical devices.

6. Home Decor and Furniture:

3D printing is transforming the way we design and create home decor and furniture. From intricate ornaments and decorative objects to functional furniture pieces, the technology enables the creation of unique and personalized items that add character and style to our living spaces.

Benefits:

- Unique and Personalized Designs: 3D printing allows for the creation of custom home decor and furniture pieces that reflect individual taste and preferences.

- Enhanced Functionality: 3D printed furniture can be designed with specific functionalities, such as integrated lighting, storage compartments, or adjustable features.

- Sustainable Production: 3D printing reduces waste and material consumption compared to traditional manufacturing methods.

- Affordable Customization: 3D printing makes custom home decor and furniture more accessible, allowing individuals to create unique pieces without breaking the bank.

FAQs:

- What materials are suitable for 3D printed home decor and furniture? Materials like PLA, ABS, wood filament, and resin are commonly used, offering a range of aesthetics and durability.

- How can I design and create my own home decor and furniture using 3D printing? Various online platforms and design software tools are available, offering templates, customization options, and 3D printing services.

Tips:

- Explore design resources: Utilize online platforms and design software that offer templates and resources for home decor and furniture.

- Consider material properties: Select materials that align with the intended use and aesthetic of the home decor or furniture piece.

- Experiment with finishes: Explore different finishing techniques, such as painting, sanding, or adding textures, to enhance the visual appeal.

7. Toys and Games:

3D printing has opened up a world of possibilities for toy and game design. The technology enables the creation of custom toys, game pieces, and even entire board games, fostering creativity and imagination in children and adults alike.

Benefits:

- Personalized Toys and Games: 3D printing allows for the creation of custom toys and games tailored to individual interests and preferences.

- Enhanced Play Experiences: 3D printed toys and games can be designed with unique features and functionalities, enhancing the play experience.

- Educational Value: 3D printed toys and games can incorporate educational elements, teaching children about STEM concepts or history.

- Sustainable Production: 3D printing reduces waste and material consumption in the toy and game industry.

FAQs:

- What materials are safe for 3D printed toys? Materials like PLA, ABS, and non-toxic resins are generally considered safe for children’s toys.

- How can I design and create my own toys and games using 3D printing? Design software and online platforms offer templates, tools, and resources for creating custom toys and games.

Tips:

- Prioritize safety: Ensure the materials used for 3D printed toys are non-toxic and meet safety standards.

- Consider age appropriateness: Design toys and games that are suitable for the intended age group, considering factors like size, complexity, and safety.

- Embrace creativity: Encourage children to design their own toys and games, fostering their imagination and problem-solving skills.

Conclusion:

3D printing continues to transform various industries and aspects of our lives, offering endless possibilities for innovation and creativity. From functional prototypes to personalized products, educational tools, and artistic expressions, the technology empowers individuals and businesses to create objects that were previously unimaginable. As we move forward, 3D printing is poised to play an even greater role in shaping our future, pushing the boundaries of design, manufacturing, and human ingenuity.

Closure

Thus, we hope this article has provided valuable insights into A Comprehensive Guide to the Top 3D Printing Projects for 2023. We thank you for taking the time to read this article. See you in our next article!